AM being still a young production technology, mastering it is a cumbersome process with many trials and errors resulting in a higher cost of production.

Despite being a modern technology, there are still many manual tasks taking longer than they should: Manual quotation, manual order's nesting, manual scheduling of build and parts, downloading machine logs, manual OEE computation.....

Over the whole production value chain of an AM part, tons of paper documents need to fill requiring operators' time that could be better spent at producing more. Manual traceability is also a risky task as we are only humans.

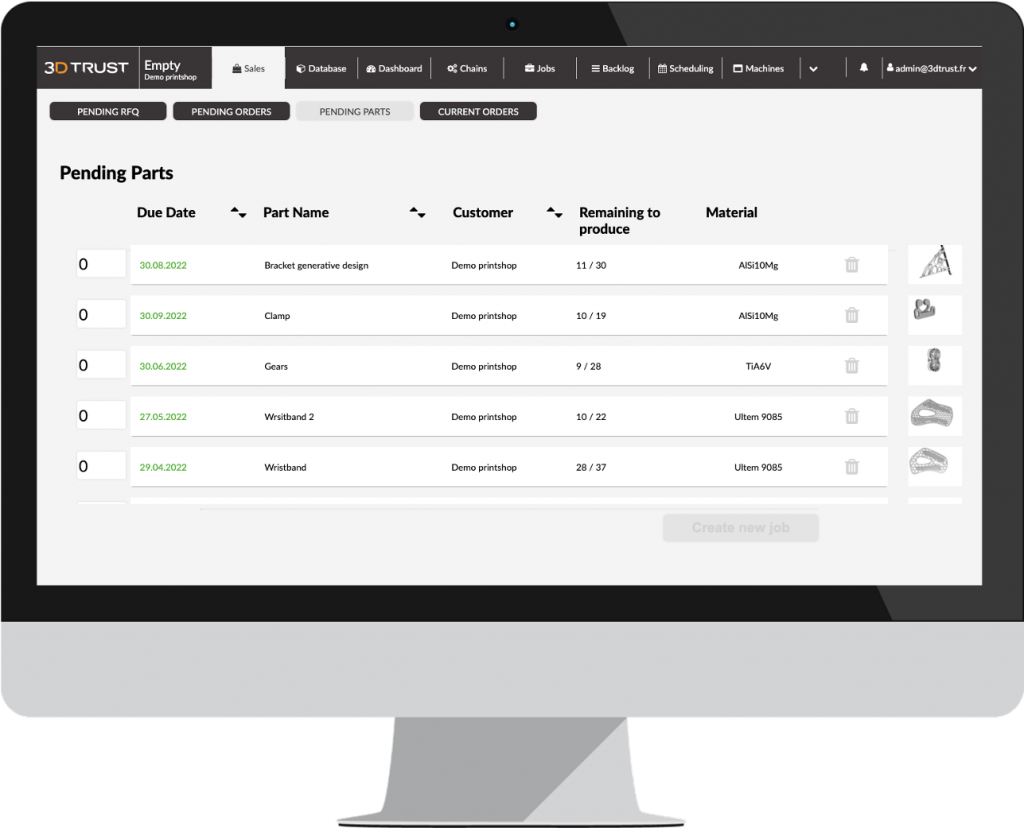

Easily centralize incoming requests from internal and external customers. Generate routing for each part and group different orders into the build to provide accurate quotations. Track orders’ progress on the shopfloor with real-time status and meet deadlines.

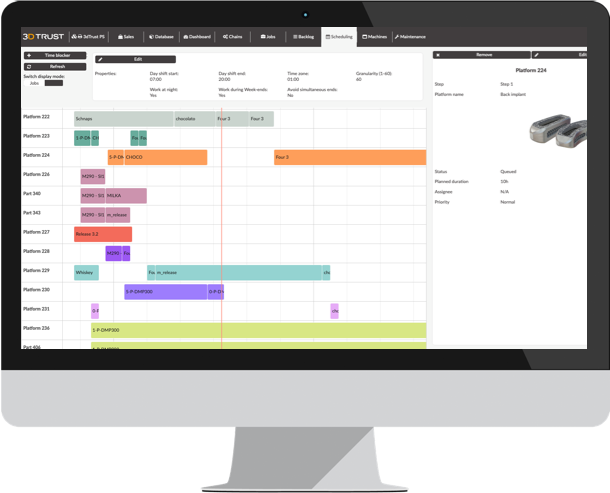

The scheduling algorithm saves you time by automatically allocating builds and parts on the right machines depending on their availabilities and performance. With machine connectivity, you are able to track in real-time the status for each build and part.

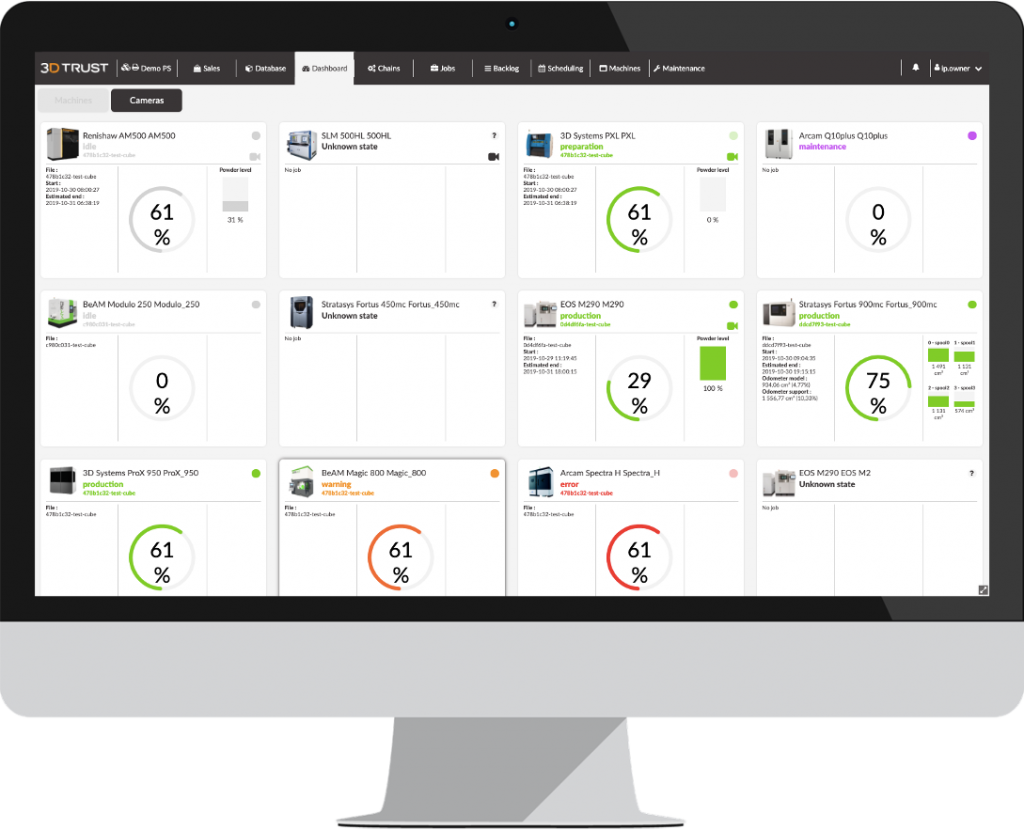

The software manages and monitors production on all major industrial printer brands. Remain connected to your machines with real-time notifications. Increase the productivity of your production process by maximizing uptime.

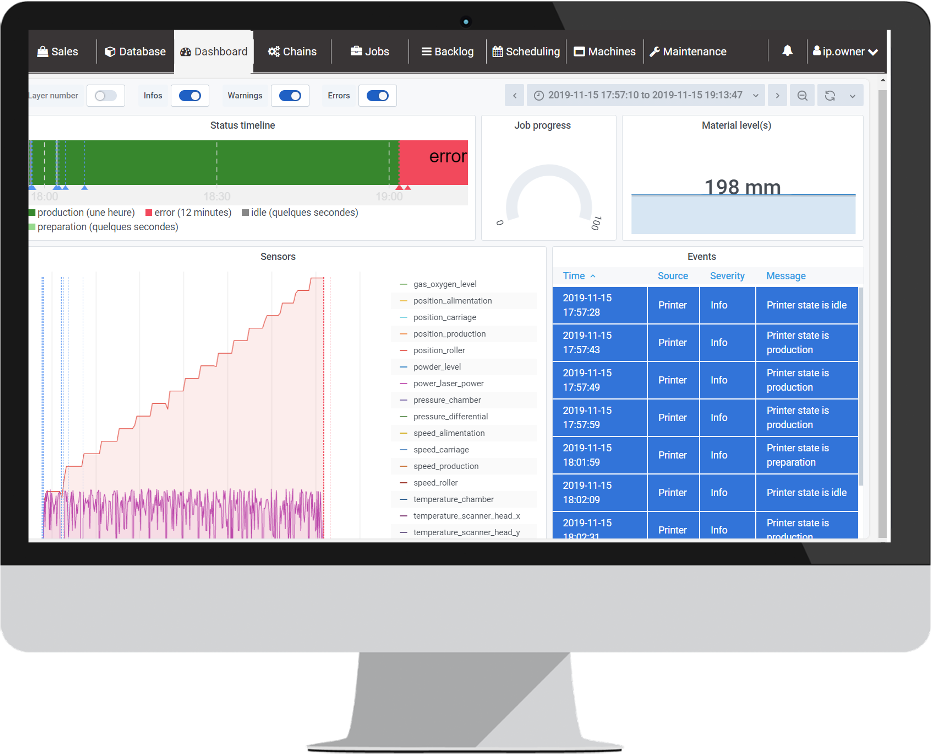

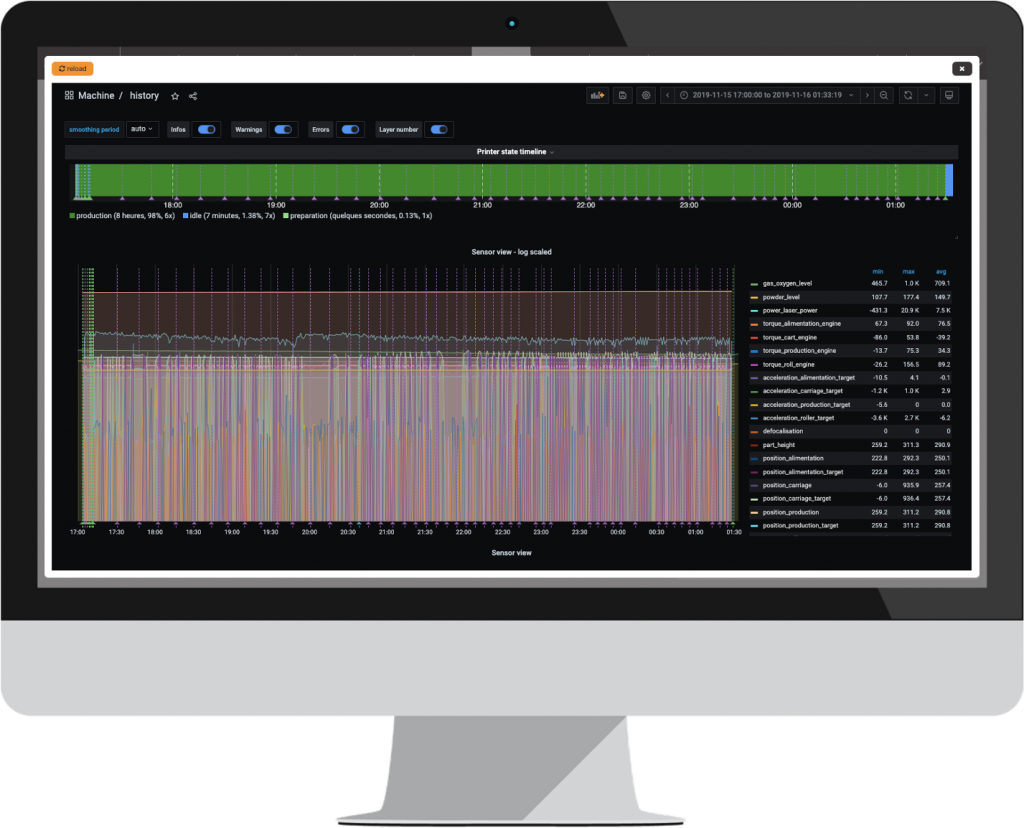

Being connected to the machines enables to gather sensors data in real-time, warning, logs, melt pool and layers images for each job. 3DTRUST AI algorithm compares the current job to the dataset that has been created with the past X prints and identifies deviations that are notified to the operators potentially saving useless printing time, wasted materials, and unnecessary post-treatments.

Monitor each machine’s efficiency, the number of parts printed, materials consumed, print fail/success statistics, maintenance history, and more. Identify the bottlenecks on your shop floor and identify the right action to improve your productivity.

MES Software - 3DTRUST - 3D printing planning and scheduling, build quality monitoring and investigation, real-time dashboard

AM being still a young production technology, mastering it is a cumbersome process with many trials and errors resulting in a higher cost of production.

Despite being a modern technology, there are still many manual tasks taking longer than they should: Manual quotation, manual order's nesting, manual scheduling of build and parts, downloading machine logs, manual OEE computation.....

Over the whole production value chain of an AM part, tons of paper documents need to fill requiring operators' time that could be better spent at producing more. Manual traceability is also a risky task as we are only humans.

Easily centralize incoming requests from internal and external customers. Generate routing for each part and group different orders into the build to provide accurate quotations. Track orders’ progress on the shopfloor with real-time status and meet deadlines.

The scheduling algorithm saves you time by automatically allocating builds and parts on the right machines depending on their availabilities and performance. With machine connectivity, you are able to track in real-time the status for each build and part.

The software manages and monitors production on all major industrial printer brands. Remain connected to your machines with real-time notifications. Increase the productivity of your production process by maximizing uptime.

Being connected to the machines enables to gather sensors data in real-time, warning, logs, melt pool and layers images for each job. 3DTRUST AI algorithm compares the current job to the dataset that has been created with the past X prints and identifies deviations that are notified to the operators potentially saving useless printing time, wasted materials, and unnecessary post-treatments.

Monitor each machine’s efficiency, the number of parts printed, materials consumed, print fail/success statistics, maintenance history, and more. Identify the bottlenecks on your shop floor and identify the right action to improve your productivity.

MES Software - 3DTRUST - 3D printing planning and scheduling, build quality monitoring and investigation, real-time dashboard