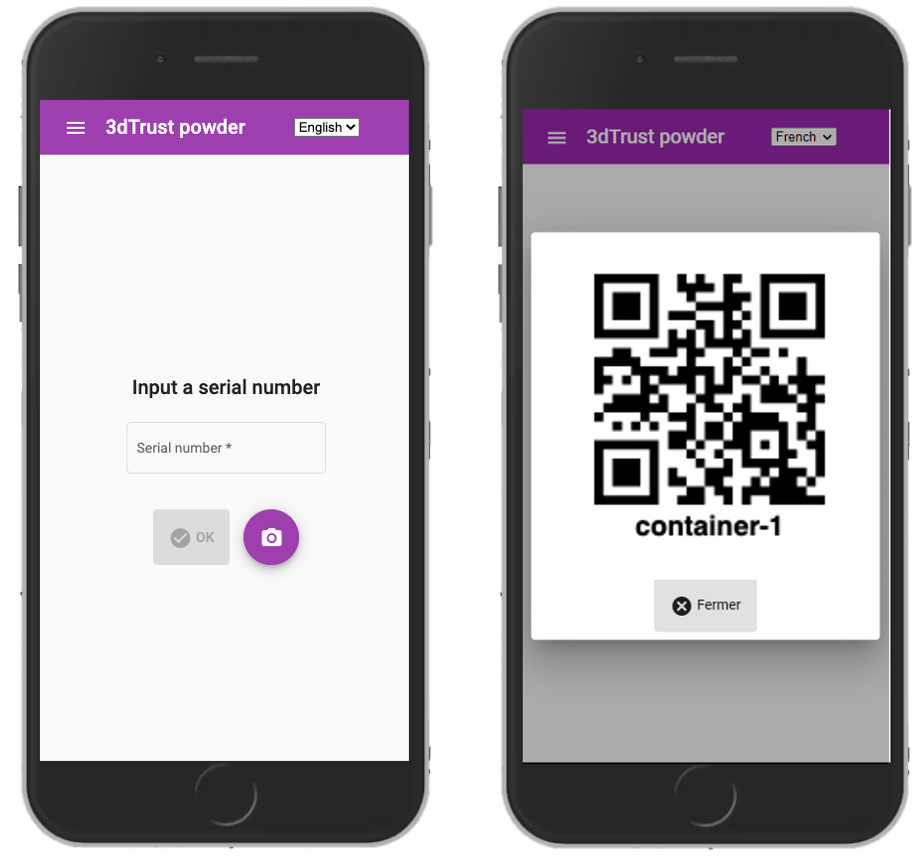

QUICKLY IDENTIFY BOXES/CONTAINERS WITH QR CODE SCANNING

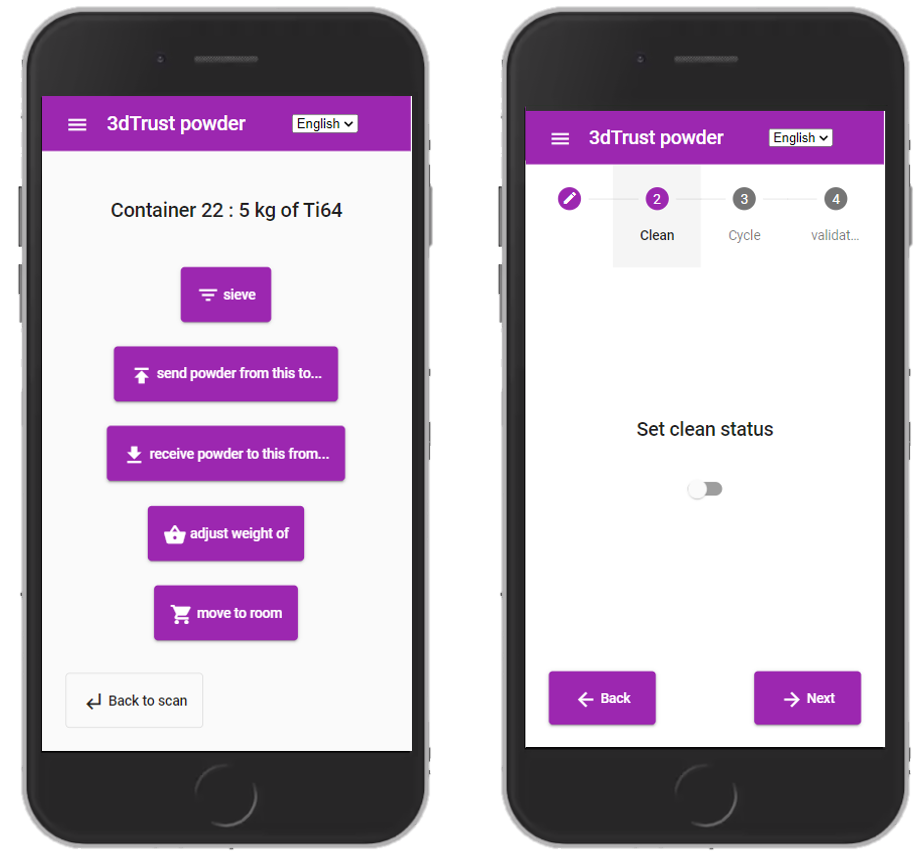

Each powder boxes/containers/machines have a QR Code stuck on them allowing mobile scanning with the 3DTRUST mobile application. The QR Code acts as a serial number enabling unique identification powder boxes/containers which is saving time for the operators.